Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Contact Us

Ultrasound equipments

-

Products

- Diagnostic softwares

- Portable vibration devices

- Precision laser shaft alignment

- Termokamera, Hőkamera

- Ultrasound equipments

-

Vibration monitoring equipments

- Cables & Connectors

- Junction Boxes

-

Mounting Hardwares

- Accelerometer Installation Tool Kit

- Accelerometer Quick Disconnect

- Adhesive Mounting Pads

- Adhesives

- High Frequency Magnet System

- Motor Fin Mount Probe Pads

- Multi-purpose Rare Earth Magnetic Bases

- Probe Tips for Portable Measurements

- Rare Earth Magnetic Bases, Flat Surface

- Sensor Protector

- Specialty Mounting Adapters & Studs

- Online vibration monitoring equipments

- Signal conditioners

- Testers, accessories

- Vibration sensors

- Vibration protection

- Services

- Training

Viewed products

-

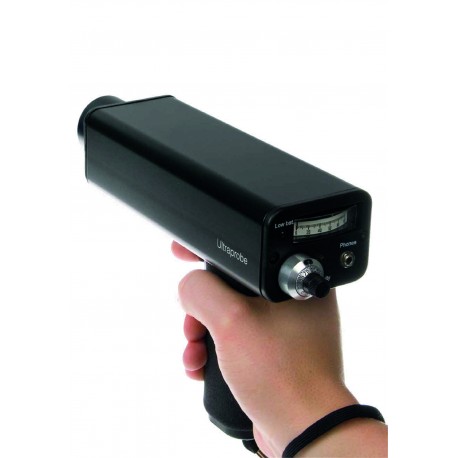

Ultraprobe® 2000 - Analog Ultrasonic inspection system

Analog Ultrasonic inspection system.

Ultraprobe® 2000 - Analog Ultrasonic inspection system

New

Analog Ultrasonic inspection system.

Ultraprobe® 2000 - Analog Ultrasonic inspection system

The Industry’s Most Comprehensive Analog Detection System

Fast, accurate, and designed for ease of use, it often takes no more than 15 minutes to become competent in ultrasonic testing using the Ultraprobe® 2000

The Ultraprobe® 2000 can help:

- Reduce unplanned downtime

- Shorten planned outage time

- Diagnose equipment problems quickly

- One person quickly test equipment in an entire section

- Create more efficient scheduling of routine Preventative Maintenance procedures

The Ultraprobe® 2000 also enables data reporting through three modes: through auditory channels (via a headset that has been specifically selected for heavy duty industrial use), through a uniquely designed bi-modal analog meter, and through the ability to interface with vibration analyzers, & sound recording devices via the heterodyned output.

For use in hazardous environments, the Ultraprobe 2000 is rated

intrinsically safe. An ATEX model is also available.

The Ultraprobe® 2000 can be adapted to test practically any problem in operating equipment with such features as:

- FREQUENCY TUNING enables a user to tune into problem “sounds” while minimizing background interference.

- METER MODE selection adjusts the meter response from a real time response to an averaging response. This feature allows accurate adjustments for leak detection and for mechanical analysis.

The Ultraprobe® 2000 can heterodyne ultrasound into audible range providing accurate sound reproduction.

Sensitive only to ultrasonic frequencies, the Ultraprobe 2000 will not respond to the low frequency noises often associated with most plant equipment. Therefore, the “gun” can be effectively utilized in extremely loud environments.

One Analog Instrument to Test Them All!

Contact Applications including:

- Bearings

- Gear Boxes

- Line Blockage

- Steam Traps

- Valves

- Compressors

- Motors

- Pipes

- Flow Direction

- Underground Leaks

Airborne Applications including:

- Vacuum Leaks

- Welds

- Substations

- Heat Exchangers

- Seals

- Pumps

- Tanks

- Air Brakes

- Gaskets

- Pressure Leaks (all types)

- Electrical Arc (including CORONA)

- Caulking (air infiltration)

- Wind Noise Problems

- Junction Boxes